Copyright © 2022.Navyugelectric.

Head Office in Ahmedabad

Plot No.4, Phase -II, GIDC Industrial Estate, Vatva, Ahmedabad, Gujarat, 382445

Request a Quote

Looking for a quality and affordable builder for your next project?

Call Us

99250 43548

Working Hours

We are happy to meet you during our working hours. Please make an appointment.

Head Office in Ahmedabad

Plot No.4, Phase -II, GIDC Industrial Estate, Vatva, Ahmedabad, Gujarat, 382445

Request a Quote

Looking for a quality and affordable builder for your next project?

Call Us

99250 43548

Working Hours

We are happy to meet you during our working hours. Please make an appointment.

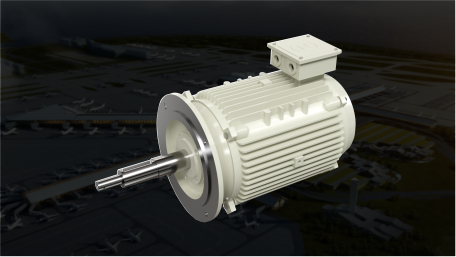

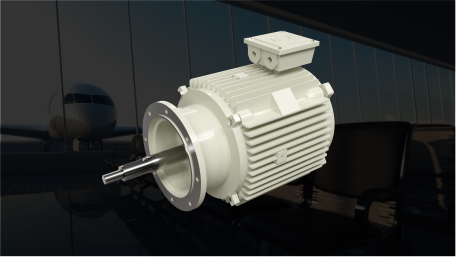

Cooling Tower Motors

Description:

Features:

0.5 - 50HP

4, 6, 8, 10, 12, 14, 16, 20, 24, 30, 32 pole motors are available

71, 80, 90S, 90L, 100L, 112M, 132S, 132M, 160M, 160L, 180M, 180L, 200L, 225M, 250M, 280M, 315L

Three Phase motors

IE2, IE3 and higher efficiency classes

TEAO enclosure, highly suitable for outdoor applications removing the need for an external fan and a motor opening in the opposite drive end by taking advantage of the airflow of the application fan itself to provide cooling to the motor.

Robust cast iron body

Volt range from 415V +- 10%, with other voltage and frequency combinations available upon the customer request.

IP55 standard, higher ingress protection available as per customer requirements

Special bearings provided by SKF to achieve more reliability and a longer bearing life

Dedicated and custom stamping design done in-house to provide a higher efficiency solution

Usage of low loss CRNGO material for the stamping

Class F insulation with class B temperature rise

Copper windings and motor are vacuum impregnated, which is a standard practice for all motors.

Motors are compatible with AC drives

Space heaters are provided on request from the customer.

Pole changing, Dual speed motors are available for energy saving

Extended shaft direct driven design for low vibrations, and low wear and tear resulting in a longer uptime and low maintenance costs.

Motors are compatible with AC drives

Space heaters are provided on request from the customer.

Pole changing, Dual speed motors are available for energy saving

Advantages of Direct Driven Motors:

Wear and tear is negligible, gear motors are subject to wear and tear thus lower operating life of the motor.

A helical gear box gear produces high axial thrust on bearings which requires higher gauge of the bearings and still causes frequent failure of the bearings

Accessibility to the inner part is very limited due to a gear box.

Gear boxes required maintained oil level.

Direct driven motors have a higher efficieny than their geared motor equivalent

Direct driven motors produce higher torque than a gear motor

Direct drive motors are more reliable as the number of rotating parts are less

Low noise and vibration levels

COMMON APPLICATIONS:

High moisture working conditions as a result of working in the air stream of the cooling tower.

Cooling towers used in industries such as

- Industrial and Commerical buildings

- Hospitals

- Airports and Metro stations

- Hotels and Resorts

- Chemical Industries in processing

- Pharmaceutical Industries in processing